- CONTACT EMAIL:

- inquiry@signialuminium.com

The status of clad aluminum brazing sheet At present, most of the composite brazing plates for the main board of automobile radiators and heat exchangers in my country are two-layer or three-layer clad aluminum brazing sheet , which have ins

The status of clad aluminum brazing sheet

At present, most of the composite brazing plates for the main board of automobile radiators and heat exchangers in my country are two-layer or three-layer clad aluminum brazing sheet

, which have insufficient strength, collapse after a period of use, poor fatigue resistance, and poor heat exchange capacity.

Introduction of clad aluminum brazing sheet

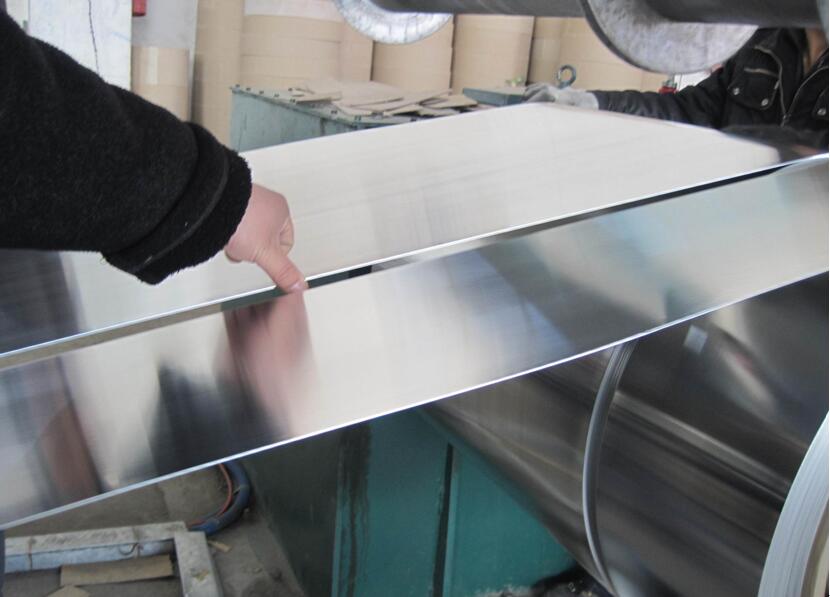

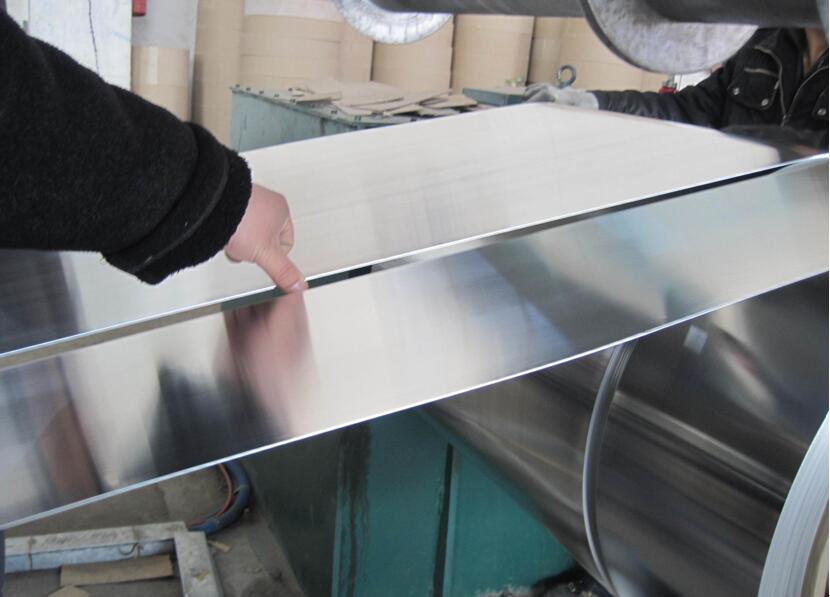

It is used in the clad aluminum brazing sheet for the main board of automobile heat exchanger. It is composed of AA4045 alloy, AA3003 alloy, and Mod6060 alloy. The above three alloys are produced. The outer layer is AA4045 alloy, the middle two layers are AA3003 alloy, and the innermost layer is After cleaning the surface of Mod6060 alloy, it is welded by sub-arc welding, hot rolling, cold rolling, and processed to a predetermined thickness of 1.5 to 2.5 mm according to a cold working rate of 20% to 30%. Recrystallization annealing is performed at this thickness, and the annealing temperature is 405°C~ 415, heat preservation for 2 to 3 hours, finished products after leveling and shearing. The role of each layer of alloys is: AA4045 alloy mainly plays a role of welding, AA3003 alloy plays a role of isolation, Mod6060 alloy plays a role of aging strengthening strength and anti-collapse.

Application of clad aluminum brazing sheet

In view of the shortcomings of existing brazed aluminum alloy two-layer or three-layer composite board materials, the clad aluminum brazing sheet produced by our company provides an aluminum alloy multilayer composite board material with high strength after brazing, fatigue resistance and strong heat exchange ability And its manufacturing method.

Mobile:86 17344894490

Email:inquiry@signialuminium.com

Address:A126 Building 4, No.89 Science Avenue,National HI-Tech Industry Development Zone,Zhengzhou,Henan