Fin Stock

Author:Frank Time:2023-05-16

DELIVERY TECH-SPECIFICATION

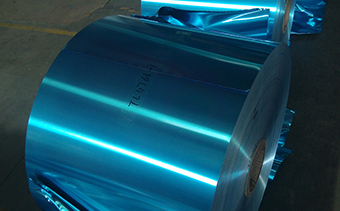

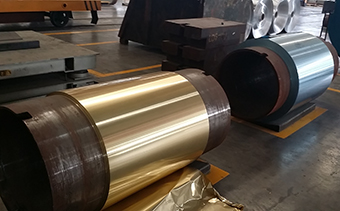

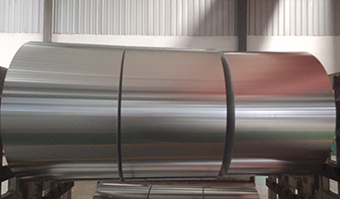

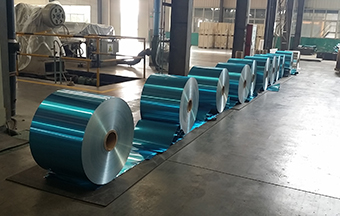

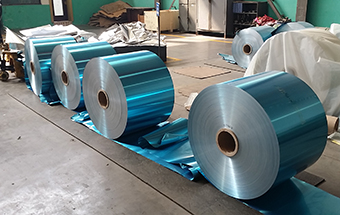

PRODUCT NAME : ALUMINIUM FIN STOCK (BARE AND HYDROPHILIC)

|

|

|---|

1. HYDROPHILIC PRE-COATED ALUMINUM FIN STOCK

2. BARE ALUMINUM FIN STOCK

3. APPLICATION RANGE

THIS SPECIFICATION APPLIES FOR HEAT-EXCHANGERS Al FIN STOCK OF AIR CONDITIONERS.

4. CHEMICAL COMPOSITION

4. CHEMICAL COMPOSITION

|

|

|---|

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | Al | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Tag No. | Per | Total | |||||||||

| 8011 | 0.50 0.9 | 0.6 1.0 | 0.10 | 0.20 | 0.05 | 0.05 | 0.10 | 0.08 | 0.05 | 0.15 | Balance |

| Remarks in the table, if there is upper and lower limit of the content, it is alloy element if the content is a single value, aluminum will be minimum limit other impurity element will be maximum limit. | |||||||||||

| 5. MECHANICAL PERFORMANCE | |||||

|---|---|---|---|---|---|

|

ALLOY NO |

TEMPER

|

THICKNESS |

TENSILE

STRENGTH

(Mpa) |

ELONGATION

(%) |

ERICHSEN (mm) |

| 8011 | O | 0.095-0.130 | 85-105 | ≥18 | ≥6.0 |

| 8011 | O | 0.130-0.160 | 85-105 | ≥19 | ≥6.5 |

| 8011 | O | 0.160-0.200 | 85-105 | ≥20 | ≥6.8 |

| 8011 | H22 | 0.100-0.130 | 100-130 | ≥17 | ≥6.0 |

| 8011 | H22 | 0.130-0.160 | 100-130 | ≥18 | ≥6.2 |

| 8011 | H22 | 0.160-0.200 | 100-130 | ≥19 | ≥6.5 |

| 8011 | H24 | 0.100-0.130 | 115-140 | ≥15 | ≥5.5 |

| 8011 | H24 | 0.130-0.160 | 115-140 | ≥16 | ≥6.0 |

| TESTING METHODS GB/T228-2002 YS/T419-2000 |

|

||||

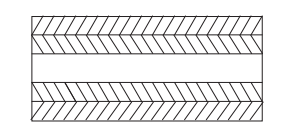

6. COATING PERFORMANCE

6.1 COATING STRUCTURE

|

HYDROPHILIC LAYER

ANTI-CORROSIVE LAYER

BASE MATERIAL

ANTI-CORROSIVE LAYER

HYDROPHILIC LAYER

|

|---|

6.2 COATING TYPES

7.

(1) FILM WITH CORROSIVE RESISTANCE ORGANIC RESIN

(2) HYDROPHILIC FILM ORGANIC RESIN

6.3 COATING PERFORMANCE

6.3 COATING PERFORMANCE

| SERIAL NO | ITEMS | TESTING METHODS | RESULTS |

|---|---|---|---|

| 1 |

SUPERFICIES AND APPEARANCE |

BY EYES |

GOLDEN, BLUE BLACK |

| 2 | FILM THICKNESS |

CALCULATED FROM WEIGHT OF FILM |

2—3µm |

| 3 |

ORIGINAL HYDROPHILIDICY |

TEST HYDROPHILICITY DIRECTLY | ≥8mm |

| 4 |

INITIAL HYDROPHILICITY |

DIP IN VAPORING OIL 3min (20±15)→VERTICAL SITUATION 7min AT NORMAL TEMPERATURE→ 210±10 DRY 2min →DIP IN PURE WATER 10min →DRY 10min/CYCLE AT NORMAL TEMPERATURE, 10CIRCLE→TEST HYDROPHILICITY. |

≥6.0mm |

| 5 | SALT-SPRAYB RESISTANCE |

JIS-Z-2371 (5%×35×72) JIS-Z-2371 (5%×35×72HOURS)

CONTINUOUS SALT SPRAY

|

≥R.NO9.5 |

| 6 | HEAT RESISTANCE |

A : 200 ×10MINS

B : 400 ×10MINS

|

A : NO CHANGES

B : TURNS LIGHT BROWN

|

| 7 | OIL RESISTANCE | DIP IN PRESS OIL 24HOURS→WASH IN FLOWING WATER→PEELTEST | NO DELAMENATION |

| 8 | ADHEWSIVE FORCE |

A. BENDING 180°

B. PEEL TEST

C. ERICHSEN VALUE=5MM

|

100% NO DELAMINATION |

| 9 | ODOR | BY NOSE AFTER DIPPING IN WATER AND DRYING NATURALLY | NO ODOR |

7.1 SIZE AND TOLERANCE

| THICKNESS | WIDTH | ||

| SIZE | TOLERANCE | SIZE | TOLERANCE |

| 0.095-0.20 | ±5% | 150-1400 | ±1 |

7.2 outer diameter of tube core and correspondence roll

UNIT : mm

| Tube core material : | Aluminum or steel |

| Tube core inner diameter : | 150, 152.4 , 200 |

|

correspondingφ150 φ152.4 φ200tube core, roll maximum outer diameter : |

1200 |

8. SUPERFICIES AND APPEARANCE

1. CLEAN NO FISH TAILS FOLDING SCRATCH AND OTHER DEFAULTS.

2. NO ADHENSIVE THINGS ON THE SURFACE NO COLOR CHANGES.

3. FLAT SIDES SHOULD BE SMOOTH AND NO CRACKS ON SIDES.

4. NO APPARENT DIFFERENCE OF COLOR BETWEEN COILS OR BETWEEN LAYERS OF EACH COIL.

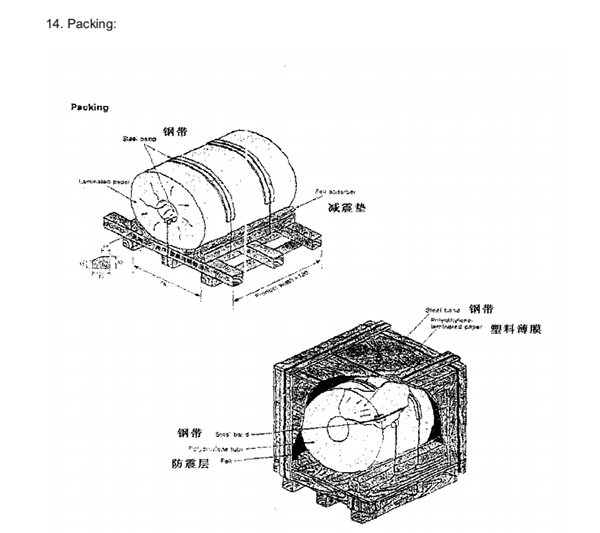

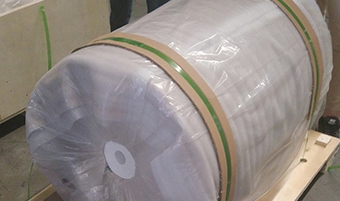

14. PACKING

|

|

|---|

9. DEMANDS OF PACKAGE AND OTHERS

STANDARD EXPORTING PACKAGE USING FUMIGATED WOODEN PALLET.

10. STORAGE CONDITIONS WARE HOUSE FOR LONG-TIME STORAGE SHOULD MEET THE REQUIREMENTS AS IT FOLLOWS

1. CLEAN DRY HUMIDITY ≤65% NO CORROSIVE GAS.

2. ABLE TO PREVENT RAIN SNOW AND WATER FROM PERMEANCE.

3. NO OTHER CHEMICAL ACTIVE MATERIALS OR HUMID MATERIALS.

11. TAB THE TAB OF EACH COIL SHOULD INCLUDE THE CONTENTS AS IT FOLLOWS

1. PRODUCT NAME

2. ALLOY & TEMPER

3. PRODUCT SPECIFICATION

4. LOT NO

5. NET WEIGHT

6. PACKAGING DATE

|

|

|---|

12. QUALITY CERTIFICATE FOLLOWING CONTENTS SHOULD BE INDICATED IN QUALITY CERTIFICATE.

1. PRODUCT NAME

2. ALLOY & TEMPER

3. SPECIFICATION

4. TENSILE STRENGTH

5. ELONGATION

6. ERICHSEN

7. QUALITY OF COATING APPEARANCE AND PERFORMANCE

8. LOT NO

9. NET WEIGHT

13. OTHERS THE ITEMS INCLUDED IN THE SPECIFICATION SHOULD BE OBSERVED BY TWO PARTIES ANY PROBLEM SHOULD BE SETTED BY NEGOTIATION.

13. OTHERS THE ITEMS INCLUDED IN THE SPECIFICATION SHOULD BE OBSERVED BY TWO PARTIES ANY PROBLEM SHOULD BE SETTED BY NEGOTIATION.

|

|

|---|