clad aluminum strip sheet

Author:Frank Time:2023-05-17

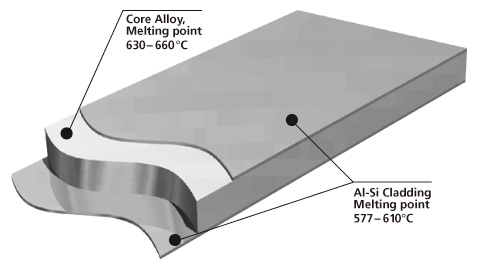

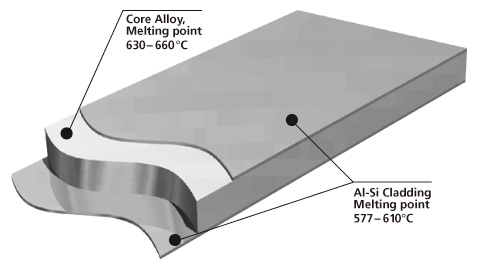

clad aluminum strip sheet comprises of a core alloy clad on 1 or 2 sides with a lower melting aluminum-silicon (Al-Si) alloy. This thin layer, usually makes up 5 % to 10 % of the total thickness of the brazing sheet.

It melts and flows during the brazing process, to provide upon cooling a metallic bond between the components. It is common that the braze clad alloy are from the AA 4xxx series or more particularly AA 4343 (Al-6.8~8.2 wt.% Si).

However, if larger fillets are desirable, or if in a situation where brazing is likely to occur at lower temperatures, AA4045 is the preferred choice.

| Dimensions | ||

|---|---|---|

| Strips | Sheets | |

| Thickness | 0.051mm--3.0mm | 0.4mm--6.35mm |

| Width | 6mm--1600mm | 500--1600mm |

| Length | Max. 10000mm | |

| Edge quality | Trimmed | Trimmed and slit; sawn |

| Inside diameter | 305mm, 405mm, 505mm Paper core, Aluminium core, without core. | |

| Outside diameter | Max. 1600mm without connect point | |

| cladding | |

|---|---|

| cladding | One side; Both sides |

| cladding rate | 5%, 7.5%, 10%, 13%, 15% (other clad percentages available upon request) |

| cladding tolerance |

cladding thickness of 1.5%--<4%: +/-0.6 cladding thickness of 4.0--6.0%: +/-1.0 cladding thickness of 6.0--<=12.0%: +/-1.5 cladding thickness of 12.0--20.0%: +/-2.0 |

| Surface | |

|---|---|

| Quality |

Mill finish; for thickness 0.3--3.5mm, chemically degreased |

| Marking | Ink marking |

1> Tolerance according to EN and ASTM.

2> Higher thickness on request.

3> Special dimensions , tolerances, and alloys on request.